- REGARDING MEDICAL DEVICE MANUFACTURING

Medical device manufacturing includes all aspects of the fabrication of a medical device, from designing a manufacturing process to scale-up to ongoing process improvements. It also includes the software and packaging of a device for shipment.

Medical device manufacturing includes all aspects from product design throughout the manufacturing process; not limited to FDA market submission and validation with strong customer focus and implementing highest quality standards.

Throughout the manufacturing process, medical device makers strive to be faster and more efficient, but they also wish to be responsible corporate citizens. Thus, manufacturing demands constant insight into renewable resources, sustainable materials, equipment that is more energy efficient, and methods to reduce waste creation. Solutions to these issues can come in the form of improved processes, technological advances in machines or equipment components, or safer/more reliable materials. The same principles apply to the packaging process.

Such “LEAN” manufacturing is considered an industry best practice: eliminating any activity, process, or material that does not add value for which a customer will pay.

Lean manufacturing not limited to process certification and stream lining the process, but to eliminate any non value added with in the supply chain in the efforts to reduce cost-savings and add value to increase customer satisfaction that meet highest quality standards with an Strive for error free product .Designs, develops, integrates advanced systems used by customers, doctors, hospitals, universities, Still, while speed and cost-savings are vital to successful manufacturing, quality control is of the utmost importance — particularly as medical device market demands shift toward a more value-driven landscape. Packaging validation, proving to the FDA that a product is sterile when it ships, is the final step. Many medical device manufacturers excel in the idea, concept, and prototyping phases of product development and outsource the production of components or entire devices to contract manufacturers. This is as true of established original equipment manufacturers (OEMs) as it is for mid-sized companies and startups. Contract manufacturers vary in size and expertise, as well — some comprise small, precise operations specializing in particular materials or components, while others are massive

2. MEDICAL DEVICE DESIGN & DEVELOPMENT

Medical device design and development is the cyclical process of creating a device for a specific task or set of tasks, and then continuously reevaluating its effectiveness and improving upon it until the device reaches obsolescence. Design and development begins with idea and the creation of a concept that, if found to be both fiscally and clinically viable, is then designed, engineered, and prototype.

Throughout the process, the proposed medical device, and the process by which it will be manufactured, is examined for flaws that may negatively impact the device’s safety, market viability, regulatory acceptance, customer satisfaction, usability, or profitability. Any shortcomings are corrected, and the improvements applied to the final design. Due to the wireless connectivity capabilities of many modern medical devices, cybersecurity and interoperability also must be incorporated into the design. Once both the product design and the manufacturing process have been validated and approved by the U.S. Food and Drug Administration (FDA), production and co commercialization of a device may begin.Our Capabilities

MANUFACTURING CAPABILITIES

3. MANUFACTURING SERVICES

process Manufacturing ,Manufacturing Processes/Lean Manufacturing 6 sigma/Process Certification

process Manufacturing software ,Process Manufacturing Software

4. SUPPLY CHAIN SERVICES

bar-code data collection solutions Bar-Code Data collection solutions/RFID Tags

5. TECHNICAL SERVICES

2D/3D Drafting ,CAD Modeling

- Software Verification Validation (SQC) software quality control Lean six Sigma

- INDUSTRY APPROVALS

- ISO 13485 Certified & Compliant Facilities

- ISO 8, Class 100,000 Clean Room

- FDA Registered Facilities

- ISO 9001

- ITAR Compliant

- Export Controls

- Federal Trade Zone Compliance

- PRODUCTS

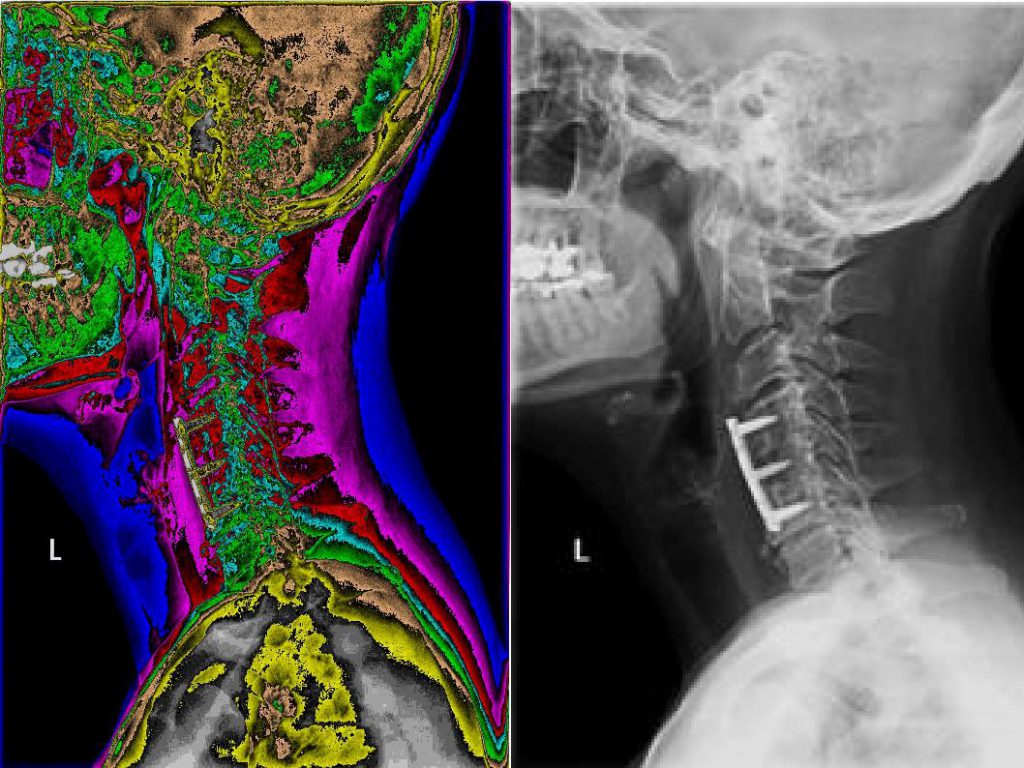

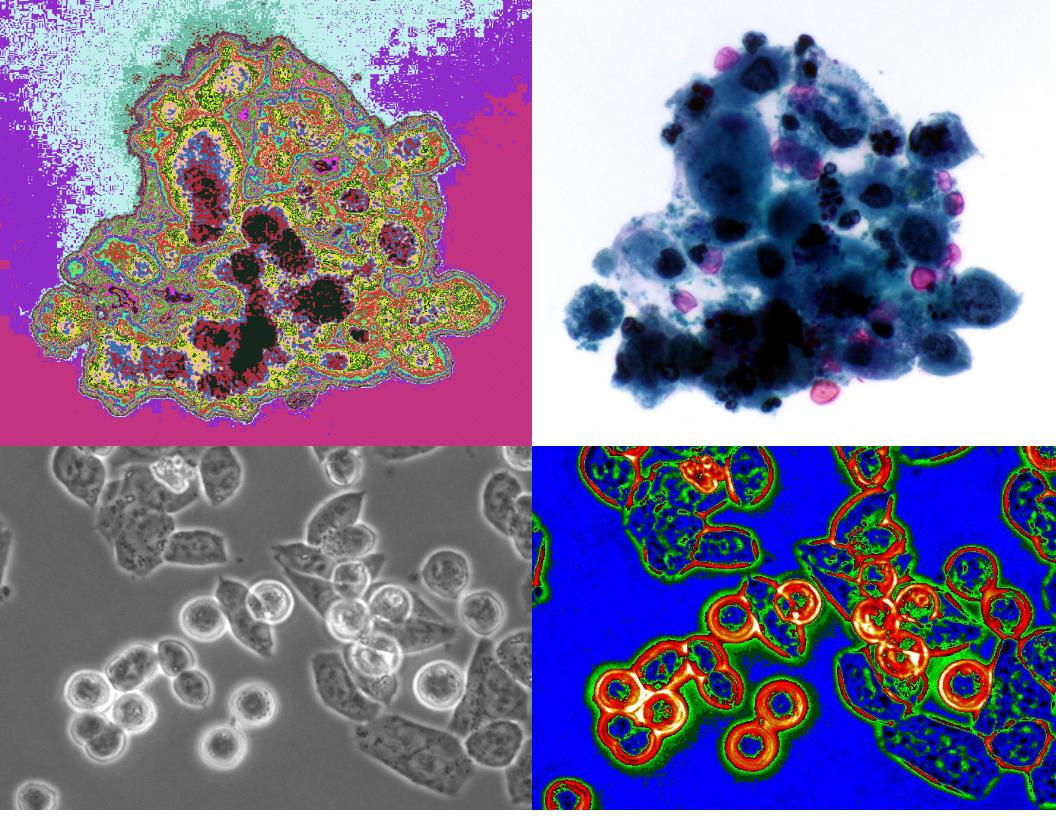

BMI MED-SEG SYSTEM

BMI FIREWALL– 2000

BMI HPC CLUSTERS